Machines for manufacturing various types of medical tapes such as adhesive bandages, gel patches, plasters, and transdermal medicines.

We have delivered a number of manufacturing lines where coating, die-cutting, inspection, stacking, packaging, and box-packing are all performed in one line.

Initial material inspection by image processing, inspection of foreign substances on products after die-cutting, and dimensional inspection can be performed as well.

-

Machine for high-speed manufacturing of poultice

Full automatic manufacturing line of poultice. Coating, cutting, stacking, packaging and cartoner.

-

Medical tape manufacturing line

Machine with widened device which can be minimum loss about the materials. From unwinding to packaging manufacturing line of medical tape. In order to avoid plaster adhere to the aluminum packaging materials, emboss also can be done.

-

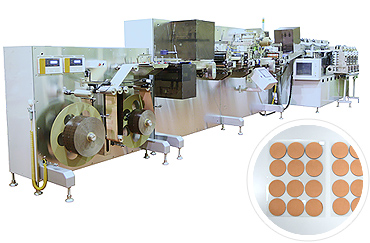

Pressure point plaster die-cutting and stacking machine

A machine for manufacturing round plasters.

The machine unwinds the initial material, checks for foreign substances on it, punches the base material only (half cut), separates the sheet, stacks the plasters, and feeds them to the box-packing process. -

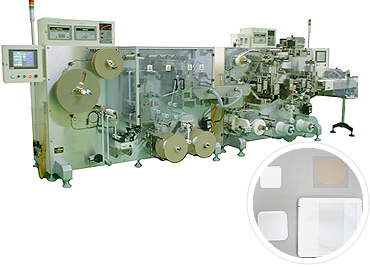

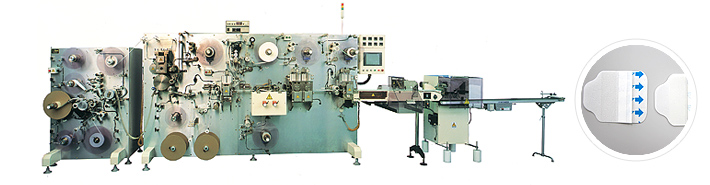

Medical tape die-cutting and four-side sealing system

A machine for manufacturing transdermal medicines for asthma or heart disorders.

In this manufacturing line, the initial material is unwound, the back is perforated, the material is die-cut, the package is sealed on four sides, and the package is die-cut. Specifications can be made to support various packaging materials. Dry edge specification is also available.View detailed information about this machine >>

Capacity Max.150 pcs/min Power 200 V AC, 2 kW Weight Approx. 1,500 kg Machine Dimensions L6,000 X H1,500 X W1,250 -

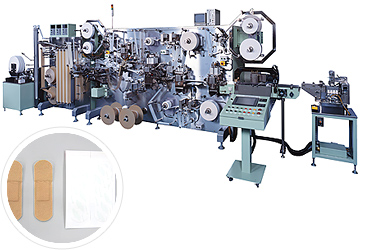

Rotary machine for high-speed manufacturing of bandage RK-M1500

A machine for manufacturing adhesive bandages using a rotary-type die-cutting system.

This high-speed machine can manufacture 1,500 adhesive bandages per minute in the regular-size punching specification. The machine supports various materials such as PVC, PE, olefin, and urethane. A cartoner can be added.View detailed information about this machine >>

Initial Material Width Tape: 80 mm,

Packaging material: 97 mmCapacity 1,500 pcs/min Cutting Method Die roll Machine Dimensions L7,200 X H2,100 X W1,300 -

Medium-size adhesive bandage manufacturing machine

A machine for manufacturing medium-size and large-size adhesive bandages using a rotary die-cutting system.

The machines supports various materials such as PVC, PE, olefin, and urethane. A cartoner can also be added. -

Hydrocolloid dressing die-cutting and packaging machine

A machine for manufacturing hydrocolloid adhesive dressings.

The machine die-cuts hydrocolloid initial material, attaches the tape and separator, die-cuts the products, and packages them.Tape Size Min. 50 X 70 to Max. 100 X 100 Sealing Method Heat sealing Capacity 150 to 250 pcs/min Machine Dimensions L6,500 X H1,900 X W1,200 -

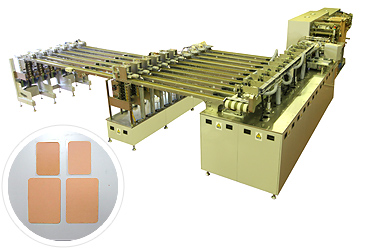

Plaster die-cutting, stacking, packing, and inspection line

A system to die-cut tape-type materials that are thinner than conventional gel patches and are now the mainstream.

View detailed information about this machine >>

Product Dimensions 100 X 70, 100 X 140 Capacity 1,500 pcs/min (100 X 140 X 3 rows) Power 200 V AC, 2 kW Weight Approx. 1,500 kg