-

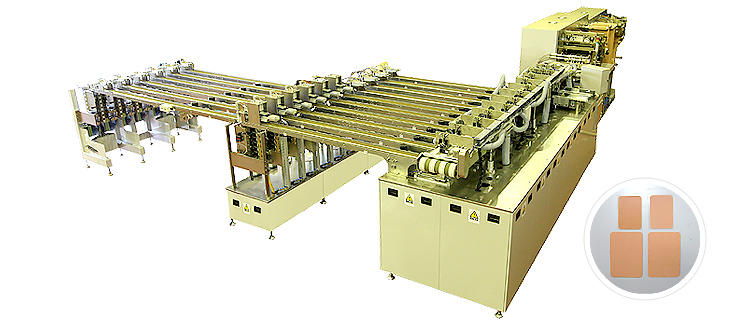

Machine overview

A system to die-cut tape-type materials that are thinner than conventional gel patches and are now the mainstream. The initial material of plasters that has gone through the process of coating and aging is unwound, checked by image inspection, and die-cut. Those that meet the standards are separated by the servo-driven bandage dropper and stacker located on the conveyor, stacked, and fed to the packaging process. The plaster size can be changed between 70 X 100 and 100 X 140 by changing the die roll.

-

Features

- Die roll method

- Servo beater

-

- Die roll method

-

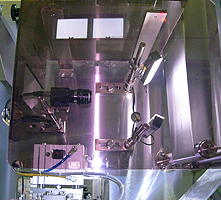

- A camera checks for foreign substances on the initial material and inspects the product dimensions at high speed.

-

- Products are automatically fed to the four-sided sealing machine that can process 110 bags per minute without any empty bags.

Machine specifications

| Initial material | Medical adhesive tape + separator | Capacity | 1,500 pieces/min (100 X 140 X 3 rows) |

|---|---|---|---|

| Product Dimensions | 100 X 70, 100 X 140 | Power | 200 V AC, 2 kW |

| Perforation in the Backing | Cut half from the separator side | Weight | Approx. 1,500 kg |